How to tighten the belt in a Samsung washing machine?

All modern Samsung washing machines are equipped with direct-drive inverter motors, the design of which does not include a belt. But washing machines produced by the manufacturer about 7-10 years ago have commutator motors with a belt drive. Therefore, if the washing machine was purchased a long time ago, the likelihood of encountering this problem increases. Let’s figure out how to tighten the belt on a Samsung washing machine, what “symptoms” indicate that the problem lies with it.

All modern Samsung washing machines are equipped with direct-drive inverter motors, the design of which does not include a belt. But washing machines produced by the manufacturer about 7-10 years ago have commutator motors with a belt drive. Therefore, if the washing machine was purchased a long time ago, the likelihood of encountering this problem increases. Let’s figure out how to tighten the belt on a Samsung washing machine, what “symptoms” indicate that the problem lies with it.

How to understand that the problem is in the belt?

It is impossible to immediately say that the drive belt has fallen off: the elastic band is “hidden” behind the rear panel and it is difficult to confirm the guess without a screwdriver. But based on some telling signs, you can understand that the problem with the washing machine stopping lies in problems with the drive. The very first and irrefutable evidence will be the signal from the self-diagnosis system.

Washing machines can automatically detect breakdowns and report them to the user in encrypted form thanks to the built-in self-diagnosis system. If the washing machine is equipped with a display, the corresponding error code will be displayed on it. You just need to find a table with a decoding suitable for a specific Samsung model, and look for the sequence that pops up among the combinations. As a rule, such lists are publicly available on the Internet. You can also find out the answers in the user manual.

But the self-diagnosis system does not always “detect” a fallen belt. Sometimes a breakdown goes unnoticed, and you need to guess about the problem through indirect “symptoms”. So, you can suspect problems with the drive in the following situations:

- The washing program is turned on, the water has filled up, the motor is running, but the drum does not rotate;

- The engine of the washing machine either hums rhythmically, then stops and “goes silent.” State changes occur at regular intervals;

- the cycle begins, the engine runs without interruption, but the electronics “freeze” and the machine does not respond to user commands;

- The washing drum rotates manually with ease, but the motor does not make noise.

You cannot operate a washing machine with a broken drive belt - the engine runs idle and overheats.

If you notice at least one of the signs listed, then you should stop the cycle and check the drive belt. We prepare a screwdriver, disconnect the washing machine from communications and begin a mini-diagnosis. To do everything correctly, follow the instructions described below.

Repair algorithm

If the belt came off for the first time, then it is enough to return it to its place. Despite its apparent simplicity, this procedure often causes difficulties. The fact is that stretching the rubber will require skill, strength and remarkable patience from the master. But even a “newbie” can cope, the main thing is to show persistence and strictly follow the instructions.

When the belt falls off regularly, it is necessary to carry out a comprehensive diagnosis of the washing machine - perhaps there is a more serious problem. The elastic band is returned to its place according to the following algorithm.

- We check that the washing machine is disconnected from the sewerage and water supply. We also disconnect the inlet and drain hoses from the body.

- We provide free access to the machine by moving it away from the wall or headset, and turn the unit with the back wall towards you.

- Unscrew the screws holding the back panel and remove it.On some Samsung machines, the top cover prevents removal of the back wall. In this case, the “top” is removed first.

- We find the drive belt. It should be located just behind the rear panel between the drum “wheel” and the motor pulley. If it is not in place, then it has flown off and is located somewhere at the bottom of the case.

- We take out the belt and assess its condition. First, we find the markings applied to the rubber, where the first four digits indicate the original diameter in millimeters. Next, measure the circumference and compare the resulting value with the factory length. If the calculated difference is equal to or greater than 20 mm, then throw away the elastic band - it has stretched too much due to long-term use and is no longer suitable for use.

If the belt has stretched 2 or more centimeters from its original length, then it is necessary to replace the rubber with a new one, more suitable in diameter.

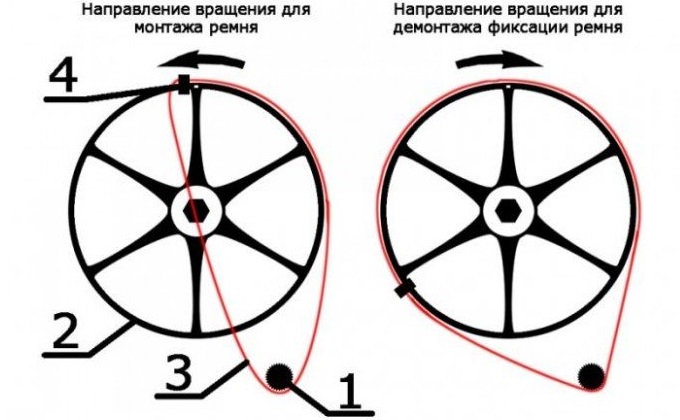

- We pull the belt onto the engine pulley, and then, carefully rotating the drum “wheel” counterclockwise, we try to put the elastic band in place. For quick results, it is better to involve an assistant, since it is easier to handle the tension with two hands than with one. But be prepared to spend a lot of time: on some Samsung models the rubber is too tight, and the manufacturer does not provide for adjustment.

- We make sure that the belt is tightly seated in all existing grooves by turning the pulley several times. If the “wheel” rotates very tightly, then the rubber is tensioned correctly.

Having visually checked the quality of work, we proceed to reassembly. We return the back wall to its place and fasten it with the removed bolts. Then we move the washing machine to the wall or into the unit and connect it to communications.Be sure to run a test wash and check that the machine is functioning properly.

Recurrence of malfunction

If the rubber band breaks off the pulley periodically, this may indicate certain problems in the system. When the belt falls off more than 2 times within 6 months, you need to be wary and diagnose the “home assistant”. The main reasons for repeated flying off of an element from the functional wheel of the drum and the motor can be considered:

- drive belt wear. Very often it falls off precisely because of its natural stretching. If there are traces of wear on its surface, the wedges are selectively ground off, the length has noticeably increased in comparison with the factory one, it means that the elastic band has exhausted its service life and needs to be replaced;

- pulley play. In such a situation, the belt is not securely fixed to the wheel and will periodically fly off when the drum rotates. Dealing with the problem is quite simple - just tighten the mounting bolt or replace the pulley;

- weak fixation of the electric motor. The motor of the Samsung washing machine is securely fastened, but due to the constant vibrations of the machine during operation, the bolts can become loose and the engine becomes loose. This leads to disruption of the belt drive. To fix the damage, fix the engine in place by tightly tightening all its fasteners;

- incorrect shape of the shaft or functional wheel. After an unsuccessful repair, during which the “unfortunate masters” bent the pulley, problems with the drive belt may begin. There is a way out of the situation - you can carefully straighten the uneven surface, but the best option would be to completely replace the pulley;

- cross defect. In some cases, users of a Samsung washing machine may experience damage to the shaft and cross.This can happen either due to the fault of the manufacturer (if there is a manufacturing defect) or due to vibrations generated by the washing machine during operation. The crosspiece must be changed, otherwise a defective part can lead to imbalance of the drum and provoke a more serious problem with the MCA;

- broken bearings. Very rarely, users bring their automatic machine to this state, but it still happens that a defect in the bearings leads to “distortion” in the system and, as a result, the belt comes off. The problem can only be fixed by replacing the drum bearings and oil seal.

Errors made during previous repairs of the element can also lead to periodic decline.

We are talking about installing the drive belt not completely - if it was not secured in the grooves, sooner or later another fly-off will occur. It also happens that the elastic band is not replaced with a similar one, but somewhat different from the original. Then we can also expect it to fail. To prevent the belt from falling off, it is necessary to replace the element with a new one that is suitable for the specific model of the Samsung washing machine.

So, having figured out the cause and eliminated it correctly, you can forget about problems with the belt drive for a long time and continue to use the washing machine.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment