How to tighten the belt on an Ariston washing machine?

Replacing a belt on a washing machine consists of two stages: removing the old one and installing a new one. There will be no difficulties with the first part; you only need to turn the pulley with one hand and pull off the belt with the other. But the second stage will be much more difficult, and to make it easier for you, we will tell you how to tighten the belt on an Ariston washing machine without outside help.

Replacing a belt on a washing machine consists of two stages: removing the old one and installing a new one. There will be no difficulties with the first part; you only need to turn the pulley with one hand and pull off the belt with the other. But the second stage will be much more difficult, and to make it easier for you, we will tell you how to tighten the belt on an Ariston washing machine without outside help.

Step-by-step instruction

The first step is to purchase a new belt. It is recommended to give preference to models of the same type and manufactured by the same company. Once the purchase has been made, the replacement can begin. Do-it-yourself installation of the rubber band is carried out according to the following instructions.

- We disconnect equipment from sewerage and water supply. You will need to disconnect the inlet and drain hoses from the housing.

- We install the machine in a comfortable position, moving it away from the wall, and then turn the back part towards us.

- We unscrew the screws intended to secure the rear panel, and then remove it. There are models where the back wall cannot be removed due to the top cover. In such a situation, you will need to unscrew the “top”.

- We are looking for a drive belt. It is located behind the rear panel between the “wheel” and the motor pulley. If it was not found here, then most likely it flew off and is located at the bottom of the hull.

- We remove the belt and inspect it. Initially, we are looking for a marking where the first 4 digits indicate the initial diameter in mm. Then we measure the circumference and compare the indicators with the factory length. If the resulting difference goes beyond 2 cm, then the elastic band has become unusable and cannot be used in the future.

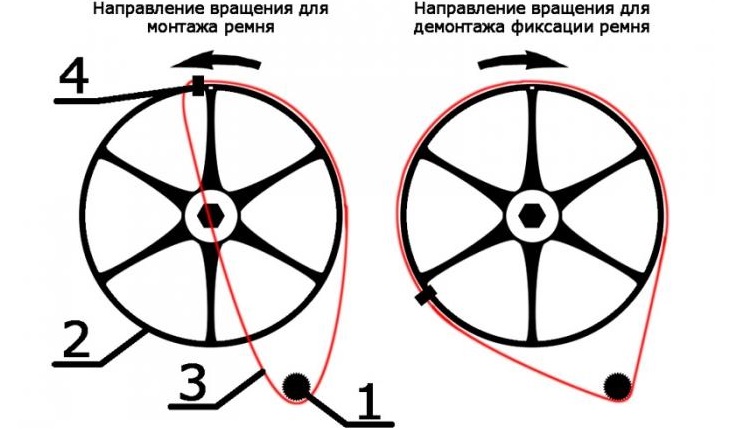

- We begin to install a new belt, which will need to be pulled onto the engine pulley, and then gradually turn the drum “wheel” counterclockwise so that the “elastic band” falls into place. To simplify the process, you can involve a friend. After all, it will be much easier to do it together.

Attention! There are models of Ariston washing machines where the belts are made of too tight a material, and the adjustment option is not provided by the manufacturer.

- Make sure that the belt is firmly seated in each groove. To do this, rotate the pulley 2-3 times. If the rotation is tight, then everything is done correctly.

After checking the work done, we begin reassembling the equipment. We install the back wall, securing it with the removed bolts. Then we return the washing machine to its original position, connect it to the water supply and activate the test wash mode to ensure the normal operation of the device.

The new belt came off again

If the installed rubber band again flies off the pulley, most likely problems occur periodically in the system. If the belt falls off more than twice in half a year, then, unfortunately, it will not be possible to do without diagnostics. Among the main reasons for this complexity are the following.

- Worn drive belt. Natural stretching is one of the most common reasons for a belt to fall off. If traces of wear are visible on the elastic band, some wedges are ground off, and an increase in length is observed, then it cannot be used for further use and an urgent replacement is necessary.

- Pulley play. In this case, the fastening of the belt to the wheel is not secure, and it will “flip” during the rotation of the drum. The problem is solved by tightening the mounting bolt more or by replacing the pulley.

- Insufficient fixation of the electric motor. During operation, the washing machine vibrates, which over time leads to loosening of the motor mounts, and it simply begins to become loose, which causes a breakdown of the belt drive. These difficulties can be eliminated by firmly fixing the motor and tightening all fastenings.

- The shaft or functional wheel is of the wrong shape. Unevenness may occur due to repairs performed by non-professional craftsmen. To get out of the situation, you must try to carefully get rid of the defect by leveling it, or completely replace the pulley.

- Cross defect. Sometimes Ariston washing machines upset owners by damaging the shaft with the cross. The fault may lie both with the manufacturer (defects at the time of assembly) and with the vibration generated during the operation of the device. If there is a defect on the crosspiece, it must be replaced. Otherwise, more serious problems may arise, leading to expensive repairs or complete failure of Ariston equipment.

- Broken bearings. Sometimes careless handling leads to the bearings becoming “distorted”, and this in turn causes the belt to “fly off”. The malfunction can be corrected by installing new drum bearings and replacing the oil seal.

Attention! Regular belt falling can also be caused by mistakes made when performing repairs yourself, or by turning to home-grown craftsmen who work on-site for clients not from the company.

As you can see, tightening the belt on an Ariston washing machine, or installing a new spare part, is not such a complicated procedure. The main thing is to purchase high-quality components recommended by the manufacturer. In this case, it is best to purchase in specialized stores, and not in the regular market. It must be the same brand and match your equipment model. Otherwise, unfortunately, it will not be possible to avoid constant belt failures, and repairing a washing machine will turn into a familiar process for you.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment