Which drum is better for a washing machine?

The drum in a washing machine takes up almost all the space, so most of the questions consumers have are related to it. Moreover, some people confuse it with a tank, which creates even more confusion. Our article will dot all the i's and explain which materials are better, whether actively advertised innovative honeycombs are any good, and how to test the drum at the stage of planning a purchase.

The drum in a washing machine takes up almost all the space, so most of the questions consumers have are related to it. Moreover, some people confuse it with a tank, which creates even more confusion. Our article will dot all the i's and explain which materials are better, whether actively advertised innovative honeycombs are any good, and how to test the drum at the stage of planning a purchase.

The best material for a washing machine tank

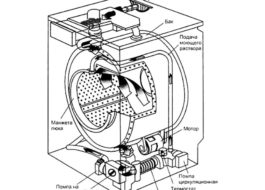

First, let’s determine what elements of the washing machine we are talking about. The tank is the main container of the washing machine, where water and detergents are supplied and the heating element, sensors and drum are located. The latter, in turn, has a cylindrical shape and is intended for loading laundry.

Now let's look at the materials. The drum in both budget and expensive washing machines is always made of stainless steel. Tanks come in different varieties, and the consumer will have to choose from three options.

- Enameled steel. It is practically not used, despite its reliability, resistance to corrosion, temperature changes and splits during transportation. Steel tanks have one big disadvantage - with the slightest chip or crack, the enamel cannot cope with its protective function, the material rusts and becomes unusable. This outcome can be caused by both long-term use and accidental entry of a foreign body into the tank.

- Stainless steel. A stainless steel container, on the contrary, will last up to 100 years due to its high strength, reliability, resistance to wear and aggressive environments. There are also some disadvantages: high price, heavy weight, increased noise and vibration.Among the “cons” is low thermal insulation, which is why the machine spends a lot of electricity, constantly heating the water. There is also a high chance of running into a fake and paying for cheap and short-lived metal instead of high-quality processed steel.

- Polymers. We are talking about plastic tanks that have good performance characteristics. They are valued by consumers for their low cost, absorption of noise and vibration from a rotating drum, high thermal insulation, lightness, and absolute resistance to corrosion and chemicals. The only thing that raises doubts is the strength, due to which plastic with a service life of up to 30 years is clearly inferior to steel. However, constant developments are being carried out to improve the composition, and this period coincides with the service life of the entire washing machine as a whole. Another negative nuance is the fragility of polymers when transported carelessly or when foreign objects get inside.

Important! Each manufacturer has its own “plastic”, which includes any composite materials.

Moreover, brands are actively developing their own types of materials, complementing the standard form and assigning them a brand name. Thus, Whirlpool promotes fibran, Candy - silitech, VEKO - carferron, Bosch and Siemens - polynox tanks, Gorenje uses carbotech and polytenax, and Electrolux - carboran. Other manufacturers, including the well-known ARDO, offer a compromise: a plastic tank with a stainless steel back wall. Such machines are strong, durable, and inexpensive.

There is no clear answer to the question about the most suitable material for a tank. It all depends on financial capabilities, brand, build quality, transportation conditions and buyer’s request.It is better to focus on the technical characteristics of the washing machine and choose a “home assistant” based on capacity, energy consumption classes and efficiency.

Drum with honeycombs: what's the catch?

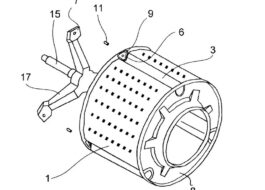

Numerous experiments have confirmed that the “grater effect” does not actually work. Convex and rough drums do not wash away dirt better, but spoil the laundry, so more and more manufacturers are trying to achieve the least impact on the fabric. An acceptable standard option involves small holes, highly polished and with concave edges. There is also a new trend - the so-called honeycombs.

The honeycomb drum is patented by Miele and differs from the usual ones by the presence on the wall and sides of the cylinder of bulges in the form of hexagons, which outwardly resemble a honeycomb. Thanks to them, a water film is formed between the loaded laundry and the metal, which enhances slip and protects the structure of the fabric. And, according to the developer, the gentleness of washing is complemented by durability and low energy consumption.

The catch with a fancy drum is one thing - the high cost is not justified. Many ordinary surfaces, well made, offer equally effective cleaning. If you choose a machine wisely, you can find a more advanced unit for the asking price.

Let's inspect the drum before purchasing equipment

If you decide which drum is best for the machine, we’ll start testing it in a store. It is extremely imprudent to trust only advertising or recommendations of a sales consultant. Therefore, we approach the model we like and begin a visual palpation examination.

- Open the hatch door and run your palm along the inner surface of the drum. Despite the irregularities and holes, your fingers should not catch on sharp protrusions or microburrs. Especially in the area of seams and holes. If there is at least one clue, pass by, as there is poor quality workmanship in violation of technology.

There is also a more reliable way - to put nylon tights or stockings on your hand. The tights will definitely catch on the micro-burr.

- We carefully feel the rib punches - plastic elements on the drum that look like blades or barriers. Here also

absolute smoothness is required, and the delimiters themselves must be held firmly in the provided grooves. If they dangle even a little, the machine does not pass the test.

absolute smoothness is required, and the delimiters themselves must be held firmly in the provided grooves. If they dangle even a little, the machine does not pass the test. - We spin the drum, checking how easily, silently and smoothly it rotates. A slight stretch is allowed, but there should be no extraneous creaks or whistles.

- Rock the container up and down, paying attention to the junction with the body. The resulting large gap clearly indicates worn bearings.

- We estimate the distance from the edge of the drum to the beginning of the hatch cuff. A length of 5 mm would be ideal, but more than 8 mm would be risky. The risk is that through such a gap small things, children's socks, panties or gloves can fly into the tank. It’s even worse when coins or other hard small items left in pockets get into the washer through the hole. They can cause a breakdown.

Checking the drum yourself is the main argument when choosing a washing machine. If there are no burrs, loose ribs or scary cracks inside the machine, then the type and material used to make the elements will fade into the background.Remember that there is a concept of “excessive quality”, and even a budget washing machine with a regular drum will last for many years if used properly.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment