The principle of operation of the drain pump in a washing machine

Today there are automatic washing machines in almost every home, but not everyone is aware of how they work. Many people only have a superficial understanding of how the drain pump works in a washing machine. Users know that the part pumps soapy water from the tank into the drain, and that's it. We will tell you what parts the element consists of and what the principle of its operation is.

Today there are automatic washing machines in almost every home, but not everyone is aware of how they work. Many people only have a superficial understanding of how the drain pump works in a washing machine. Users know that the part pumps soapy water from the tank into the drain, and that's it. We will tell you what parts the element consists of and what the principle of its operation is.

How does the pump work and where is it located?

Washing machine users rarely think about what processes the equipment performs after the cycle starts. They load laundry into the drum, pour powder into the cuvette, press the “Start” button and calmly go about their business, waiting for the end of the program. Knowing how an automatic machine works will help you quickly respond to a problem and identify the cause of the problem. Therefore, it is still worth understanding how a “home assistant” functions. So, after starting the wash, the following processes occur in the machine:

- the inlet valve opens, water under pressure begins to enter the system: it is poured into the powder receptacle through the pipes, mixed with detergent and “goes” into the tank;

- The pressure switch is activated. It measures the water level in the tank, and when there is enough of it, it sends a signal to the control module;

- the “brain” closes the solenoid valve, the fluid flow stops;

- the main cycle begins - the washing machine spins the laundry in soapy water.

The pump is activated several times during a standard cycle - at the time when it is necessary to drain the water from the tank.

The drain pump operates not only at the end of the cycle, but also after pre-cleaning (if this option is set) and during rinsing. Without a pump, an automatic machine will not be able to complete any washing program. When the module signals the need to remove water from the tank, the element immediately gets to work. The path of waste water is as follows:

- water from the tank “passes” through the drain pipe;

- enters the pump through the filter element (it protects the impeller from debris and other objects that accidentally end up in the drain);

- flows through the drainage hose connected to the volute into the sewer.

The process continues until all waste water is removed from the tank. When the pressure switch detects a “zero” filling level of the centrifuge, it will notify the control module about this. Next, the “brain” will turn off the pump. The principle of operation of the pump is clear. When the machine is operating, the water is in the lower part of the machine, where the pump and all pipes are located. That is why it is important to follow the rules for securing the drainage hose - it should be located no lower than 50-60 cm from the floor level. This will prevent spontaneous leakage of liquid from the system.

The end of the drain corrugation must be fixed above the level of the washing machine's drain pump, otherwise the water will drain away by gravity.

The pump is attached to the bottom of the machine body, under the tank. The pump is connected to the volute with three bolts. The plastic snail itself is attached to the front panel of the machine, which allows you to access it if necessary. For example, you can easily clean the debris filter or manually drain the remaining liquid from the system only by removing the false panel or opening the technical hatch door.

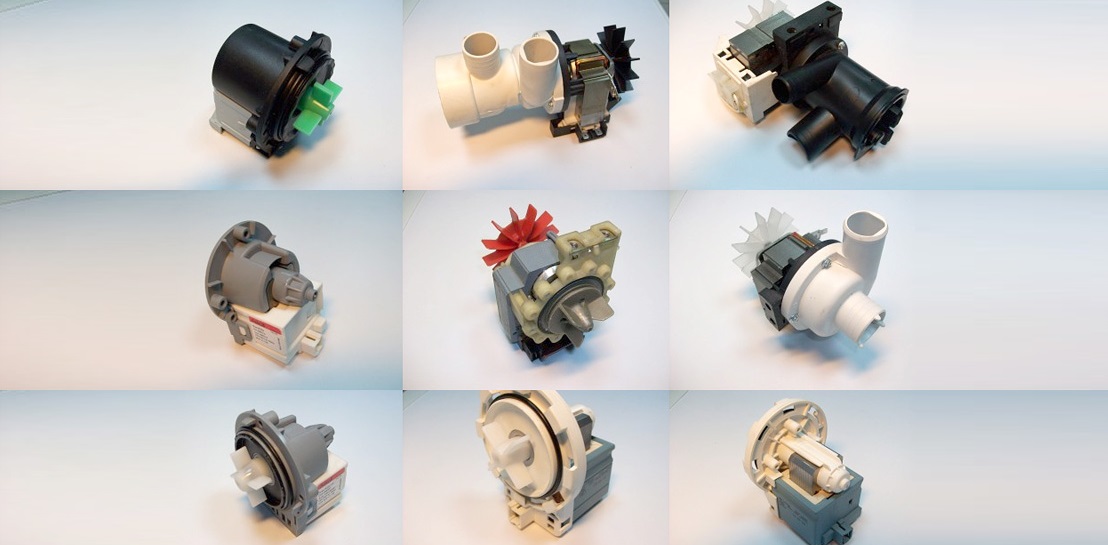

Types of pumps

If you want to go deeper into this issue, you can figure out what type of pump is installed in the automatic machine.There are only two types. It could be:

- circulation pump. It is paired with a standard pump on modern premium washing machines from brands Indesit, Ariston and others. In this case, water constantly circulates in the system, thereby increasing the washing efficiency;

- standard pump. Most washing machines are equipped with this pump. In this case, dirty, soapy water is simply drained from the tank into the sewer.

If the pump installed on your SMA burns out, it will not be practical to repair the part. In such a situation, it is necessary to buy a new pump and install it in place of the old one. Fortunately, it is now quite easy to find and order components for most brands of machines. If the part is simply clogged, you can clean it yourself. To do this you should:

- turn off the power to the machine;

- close the valve responsible for the water supply;

- drain the remaining liquid from the system through a garbage filter;

- lay the machine on its side;

- remove the pallet, if equipped;

- unhook the connected pipes from the element;

- remove the pump from the body by unscrewing the bolts holding it;

- disassemble the pump body, clean the “insides” of debris and dirt, remove threads, lint and hair wound around the impeller.

Then the pump is assembled and installed in its original place. You can remove debris from the impeller without removing the pump from the housing. To do this, just unscrew the garbage filter and, through the resulting hole, get out everything that is wrapped around the blades.

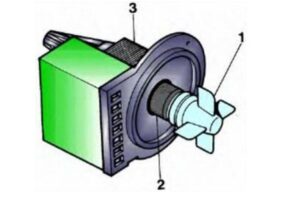

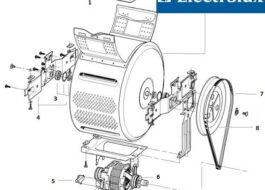

What elements does the part consist of?

There is nothing complicated about the drain pump design. The pump rotor is a magnet made in the shape of a cylinder. It is “hidden” in a plastic casing. After starting the system, the rotor is activated first, then the impeller located on the shaft begins to rotate.

There is an insulating winding on the magnetic core. The design of the pump is similar to an asynchronous motor, which also has moving (rotor) and stationary (magnetic rod with winding) parts. This is how the pump functions. If any of its components are damaged, for example, the impeller impeller breaks, you will have to install a new pump. There is no point in repairing the part - it will only be a temporary measure.

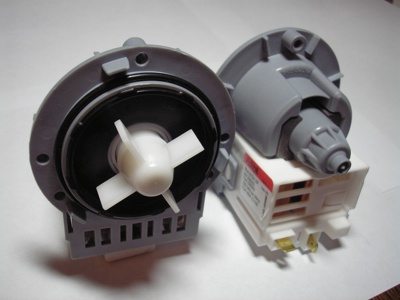

The circular type pump also has a sealing collar. It serves to prevent water from pouring into the bearing assembly. These mechanisms are additionally equipped with a rotor shaft passing through a lip sleeve compressed by a spring ring. The standard SMA drainage pump is characterized by the following technical parameters:

- power – 25-40 Watt;

- placement of contacts: paired or separate;

- type of connection to the cochlea: screw or using snap fasteners.

If you need to replace the pump of an automatic machine, you need to buy a new part based on the characteristics of the old spare part. Otherwise, the purchased pump may simply not be suitable, and the money will be “thrown down the drain.”

Drain pumps for washing machines differ in power and location of contacts, as well as in the type of volute and the filter element placed inside them. Therefore, when selecting replacement components, be sure to focus on the model of your washing machine. It is worth keeping in mind that if the garbage filter is clogged, the water may not leave the tank in full. Dirty fluid remaining in the system causes an unpleasant odor. To fix the problem, you need to clean out the trash can.

Cleaning the garbage filter is easy to do yourself. To do this, you need to turn off the power to the machine, turn off the water supply tap, and cover the floor around the washing machine with dry rags. The “plug” is located in the lower corner of the case, behind the decorative panel or technical hatch door. Unscrew the element from the machine, rinse in warm water, wipe the walls of the hole, remove the accumulated debris from inside and put the “spiral” back.

What can I do to make the pump last longer?

The water pump is an integral part of any washing machine. Manufacturers guarantee that if the equipment operating rules are followed, the pump will work properly for 9-10 years. Whether the “pumping station” will last that long depends greatly on the user. Many factors can shorten the lifespan of a part:

- entry of debris (paper, hair, lint, threads) into the drain system;

- accumulation of pieces of dirt on clothes loaded into the drum;

- voltage drops in the network;

- getting paper clips, hairpins, candy wrappers and other foreign “things” from the pockets of things into the pump.

In order for the drain pump to work flawlessly, it is important to follow several rules:

- shake out the laundry before putting it in the drum;

- check the pockets of things - they should be empty;

- pre-soak very dirty laundry in a basin and only then load it into the machine;

- use special water softeners to reduce the likelihood of scale formation;

- Make sure that the water is completely drained from the tank upon completion of the wash.

It is advisable to place a filter in front of the washing machine's inlet hose - then the hard water entering the system will be further purified and softened.

If it seems to you that the machine has begun to drain water worse, it is better not to put off diagnosing the unit.By identifying a breakdown in the early stages, you can eliminate it at the lowest cost. If you start the process, you may have to change not just a single part, but the entire washing equipment. To repair the machine, you can invite a specialist or understand the structure of the unit and fix the washing machine yourself. It is important not to forget about safety rules. They must be observed when working with electrical appliances.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment