How to put a belt on a washing machine

If you are the owner of a modern direct drive washing machine, then you have no need to worry about the drive belt falling off, since your washing machine simply does not have one. If your washing machine has a commutator or asynchronous motor, and the drum pulley rotates via a belt drive, then this publication is for you. On its pages you can get information about troubleshooting a problem with a washing machine belt.

If you are the owner of a modern direct drive washing machine, then you have no need to worry about the drive belt falling off, since your washing machine simply does not have one. If your washing machine has a commutator or asynchronous motor, and the drum pulley rotates via a belt drive, then this publication is for you. On its pages you can get information about troubleshooting a problem with a washing machine belt.

How to determine a breakdown?

It is usually difficult for the average person to determine what happened to the washing machine, because if the drive belt falls off, the home assistant cannot continue washing. The drive belt is located in the body of the washing machine and there is no way to see that it has fallen off, but by some signs it is quite possible to understand what happened.

Most often, the washing machine itself notifies the user about the breakdown and its nature through the built-in self-diagnosis system. Thanks to this system, it costs nothing for the machine to immediately react to a breakdown, stop the operation of all systems and display an error with a certain code on the display.

The error code depends on the brand and model of the washing machine, so when such an error appears, the user’s task is to look at the table of error codes for a specific “home assistant”. Having such a table in your hands, you can easily decipher the error code that appears on the display of your washing machine. You can find such information, in particular, on the pages of our website.In a number of publications, we have deciphered almost all error codes for most models of washing machines, so there will be no problems finding information.

It happens that the washing machine does not display an error code, but a breakdown still occurs. In this case, the fact that the belt has come off and needs to be put on is confirmed by a number of indirect signs.

- The washing program starts, the motor runs, but the drum does not rotate;

- The washing machine motor hums evenly, and then “goes silent” at equal time intervals;

- The program starts, the engine starts to run continuously, after which the electronics freeze.

- The drum of the washing machine rotates manually very easily, and such rotation does not cause even the slightest noise from the engine.

If any of the above signs are present, this is a good reason to turn off the washing machine, remove the back wall and look at the drive belt with your own eyes.

We fix the breakdown

The problem is that often a flying belt is just a consequence of some more serious problem. If the belt on your washing machine came off for the first time and this is an isolated incident, then you just need to put it back on. This is not always easy to do, but not because it is some kind of complex repair, but because it requires skill and sometimes remarkable physical strength. In general, the order of work looks like this.

- Disconnect the washing machine from the electrical network and turn off the water. Then disconnect the drain and inlet hoses.

- We take the washing machine out into the middle of the room to make it easier to work with, and turn it with the back wall towards us.

- The belt is located just behind the back wall, tensioned between the large drum pulley and the motor pulley, so we remove the screws holding the back wall in place and then move it out of the way.

In some cases, the top cover prevents you from removing the back wall of the washing machine. Then you must first remove the top cover, and then remove the back wall.

- Behind the back wall you will either see a belt put on the pulleys and then the information that it has fallen off will not be confirmed, or the belt will be lying somewhere at the bottom of the washing machine body, and you will need to put it in place.

- If the belt has come off, we pull it out of the washing machine body, and then try to read the set of numbers and letters printed on its surface. We will be interested in the first 4 digits - this is the initial length of the belt in mm. We will need to measure the belt, comparing its actual length with the length declared by the manufacturer. If a difference of 20 mm or more is detected, such a belt is only suitable for ejection. If the length matches, you can pull the old belt back on.

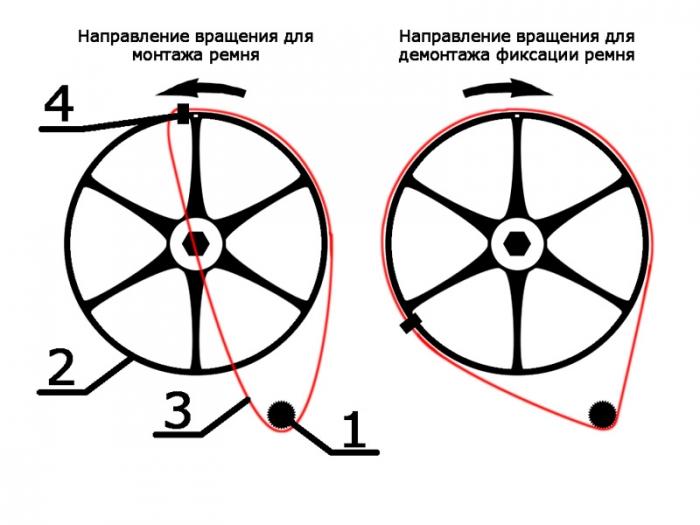

- Next, you need to pull the belt onto the engine pulley, and then try to put it on the large drum pulley while simultaneously rotating this pulley counterclockwise with one hand. You can ask someone to help you rotate the pulley while you try to tighten the belt with both hands. On some models, the belt is very difficult to tension, and the manufacturer did not provide for adjustment.

- As a result, the belt should fit normally into all grooves; rotate the drum pulley and make sure that this is the case. The pulley should turn quite tightly by hand.

- We put the back wall in place, push the washing machine into the niche and connect it to the communications.Now all that remains is to run a test wash and make sure everything works fine.

If the failure reoccurs

Much more serious problems can result from the drive belt falling off multiple times. If the belt has come off at least a couple of times in six months, this should already alert you, because this is almost certainly a consequence of a more serious breakdown. What are the reasons for the belt often flying off the engine pulleys and drum?

- The belt has expired. A fairly common reason for the belt to constantly fly off. If the belt has signs of wear, the wedges are partially ground off, and the belt itself is partially stretched, it is necessary to replace the belt with a similar one.

- There are signs of wear on one of the pulleys, or it has become loose. If there is play on the pulley, the belt will not stay on it during rotation. The problem is solved by tightening the pulley fastening element, or by completely replacing it.

- Engine mounting problems. On most washing machines, the motor mount is very reliable, but due to constant vibration it can become loose and the bolts can become loose. As a result, the belt does not stay on the pulleys. Solution to the problem: strengthen the engine, tighten all fasteners.

- The pulley and shaft are irregularly shaped. Our specialists have encountered situations where, as a result of a previous unsuccessful repair, the average person himself or some “would-be master” bent a pulley, after which problems with the drive belt began. The problem is solved by replacing the pulley or carefully straightening it. In the latter case, a solution to the problem is not guaranteed.

- Problems with the cross. It's not common, but it does happen that the shaft and crosspiece get damaged. Maybe vibration or a manufacturing defect is to blame, or maybe both.In any case, the crosspiece will have to be replaced, since a damaged part causes an imbalance and can cause even more serious damage.

- During the previous repair, the belt was installed incorrectly. This happens often, if, for example, last time you installed it incorrectly and missed the grooves, the belt will sooner or later fly off the pulleys again and will have to be redone.

- The belt was replaced with an incorrect one. If, again, some “unfortunate master” changed the drive belt last time, but managed to install the wrong one, there is a high probability that the new belt will constantly fly off. Solution to the problem: finding and installing a drive belt suitable for your washing machine model.

- The bearings are smashed into rubbish. Rarely do people bring their “home assistant” to such a state, but it still happens when the bearings break completely, the machine begins to work with a wild grinding noise and, as a result, a misalignment occurs. As a result of the misalignment, the belt falls off and the machine stops working. Solution to the problem: bearing replacement and seals.

In the case when the bearings of a washing machine are destroyed, a flying belt is the least of the troubles awaiting your equipment and you.

Buying a new part

A worn out belt needs to be replaced, you can’t argue with this statement. But here another question arises: how to buy a suitable spare part? The best option is to take the old belt and go to the store with it, show the damaged spare part and ask to bring a similar new one.

Unfortunately, this option is not always available to everyone.If you, for example, are a resident of a remote village where the only store is a local general store, then the most acceptable option for you would be to order spare parts via the Internet and deliver them by mail to the regional center or directly to the village, but this is easier said than done. How can I order the correct belt in this case?

There are two main types of drive belts: V-belts and poly-V-belts. If your washing machine has an asynchronous motor, most likely you will have to deal with the V-belt. If the engine is a commutator type, it means you have a serpentine belt. Having understood the general theory of drive belts, we begin to carefully read the inscription inscribed on the old belt. The first numbers (usually 4) indicate the length of the part in millimeters, then the numbers are followed by a letter indicating the shape of the wedges. The letter is followed by a number that determines the number of wedges.

All numbers and letters must be rewritten and be sure to take this information into account when ordering the part.

You will order a new belt for your washing machine taking into account: the model of the washing machine, information on the belt, and the material from which the belt is made. Taking into account all the data, you will never make a mistake when ordering.

To summarize, we note that if the problem lies only in the washing machine’s drive belt that has come off, then it is quite possible to fix this breakdown with your own hands, in some cases even without difficulty. But if a belt that constantly falls off is the result of a more serious breakdown, you cannot do without the help of an experienced technician. Happy renovation!

Interesting:

1 reader comment

Hello, what happens if you install two belts?