Where are Siemens washing machines assembled?

The policy of many modern manufacturers boils down to the fact that a trademark is registered in one state, and the assembly of products is carried out in another. Bosch und Siemens Corporation is no exception in this matter. Consumer opinions are widely divided regarding the impact of assembly location on the quality of the final product. Some believe that the service life of the equipment depends on where Siemens washing machines are assembled, while others rely on the brand’s reputation. We will tell you the truth.

The policy of many modern manufacturers boils down to the fact that a trademark is registered in one state, and the assembly of products is carried out in another. Bosch und Siemens Corporation is no exception in this matter. Consumer opinions are widely divided regarding the impact of assembly location on the quality of the final product. Some believe that the service life of the equipment depends on where Siemens washing machines are assembled, while others rely on the brand’s reputation. We will tell you the truth.

There are industries everywhere

The most honest manager will find it difficult to answer the question of where a particular washing machine was assembled. Household appliances often have two or three origins. The company's head office is located in one country, the brand itself is registered in another, and assembly is carried out in a third.

Important! Even the components themselves can be created in different places.

Why this has happened historically is clear: in order to increase revenue, manufacturers are trying to reduce the cost of the product as much as possible. That is why for renting factories they choose places where prices for necessary materials are lower and labor is cheaper. The mentality of the potential buyer, who is accustomed to trusting the quality of European equipment, is also taken into account: for example, German-assembled devices are usually purchased more actively than their Chinese and Russian counterparts. Accordingly, companies choose a simple but effective scheme: registration on European territory, location of branches locally (in our case, in the Russian Federation), assembly of goods in Asia.

Almost no one is surprised that most washing units are produced not in German states, but closer - in Slovakia, Poland and even Russia itself, where employees not only cost less, but often do not have special requirements for the workplace. However, concerns try to hide the fact of Polish or Russian assembly, and persistently indicate “Made in Germany” on household appliances. The fact is that clients react negatively to the transfer of production to a non-prestigious state.

One can understand the manufacturer: why build a new plant if another company has already launched the production of the required products. It’s easier to order the required quantity of goods there and stick your label on top. For example, you can take the Italian Siltal in Italy. The concern's nine factories produce up to five thousand units daily. Siltal is trusted by 248 brands, including Bosch und Siemens. For the latter, narrow models of washing machines are assembled here.

How did the company develop?

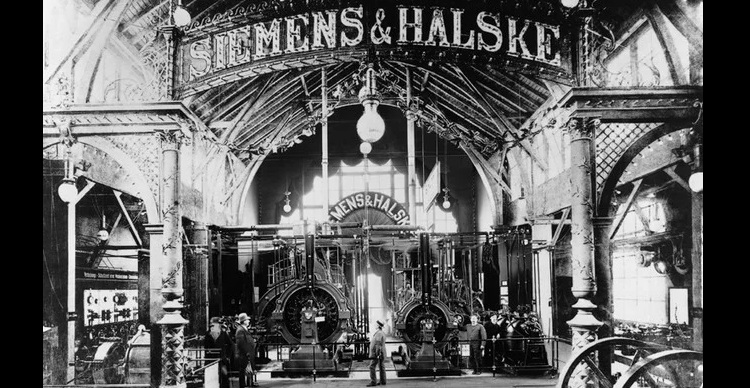

The history of Siemens began in the middle of the 19th century. Werner von Siemens, a German scientist and inventor, together with engineer Halske, founded a company producing electromechanical products. The work was carried out in the field of telegraphy, medical equipment, optics and precision mechanics. The first Siemens washing machine appeared only 81 years later, and its production is being improved to this day. Modern Siemens washing machines are:

- components made from quality materials;

- ergonomics;

- wide functionality;

- intuitive interface, ease of operation;

- saving water and electricity.

The company's products, whether German-assembled or not, are sold in 190 countries. In terms of geographic distribution, the concern is a leader along with Coca-Cola. Another impetus in development occurred after the merger with Bosch.The products entered our market after the merger of companies, and the Russian consumer received them well. Due to stable demand, it was decided to establish production in the Russian Federation.

Nowadays, the assembly of large parts has been established in St. Petersburg, so Russian-assembled products differ little from their analogues produced in Germany. The products are supplied exclusively with German spare parts, with a limited number of foreign enterprises involved in assembly. This explains the success of Bosch&Siemens technology.

Should we think about the country of assembly?

Siemens leads the rankings in terms of durability. During the first ten years of machine operation, no more than 5% of technical failures are recorded. The severity of control and testing is the same both at home and at foreign enterprises.

Important! Sales points for original equipment can be found on the company’s official website.

Detailed information about the manufacturer is indicated in the data sheet or on a special sticker. On top-loading machines it is located on the door or at the back. On products with horizontal loading - on the inside of the hatch, at the top left of the front panel, and also on the rear side.

To build a small plant to produce washing machines, an initial capital of a billion dollars is required. If you buy high-tech equipment, the place of assembly will not affect the quality. Products of this level simply exclude counterfeiting. Therefore, the risk of purchasing a low-quality unit is minimized.

Today Siemens is produced in Germany and Spain, Turkey and China. The Russian assembly includes the WS 12G240 and 10G240 models, as well as the silver WS 12G24S.But this is not particularly important: B&S will not risk its reputation by sending a defective product for release, since even for goods manufactured in another country, the company bears warranty obligations. In addition, some of the equipment is sold in the European Union, where the ISO system dictates strict quality standards. Therefore, when purchasing, it is better to focus not on the assembly location, but on the functionality of the selected model.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment