Homemade wood splitter with an electric motor from a washing machine

And in the 21st century, complete gasification of Russia remains a distant future. Not only remote villages, but many small towns are forced to rely on wood-burning stoves, for which a lot of fuel needs to be prepared every year, because the winter is long and cold.

And in the 21st century, complete gasification of Russia remains a distant future. Not only remote villages, but many small towns are forced to rely on wood-burning stoves, for which a lot of fuel needs to be prepared every year, because the winter is long and cold.

If you have the strength and health, then you can swing an ax, but if you don’t have the strength or don’t want to waste it on the dull, monotonous work of splitting knotty logs? You can turn on your head, watch a video or read our article and make a wood splitter with a washing machine engine.

Design selection

Compared to chopping wood manually, working with a wood splitter is a pleasure. There is no need to waste energy splitting logs, lifting a heavy cleaver, sweating and cursing the stove heating. When working with a wood splitter, you only feed it logs, and all the hard work of splitting them is transferred to the mechanism. Before assembling a homemade wood splitter with your own hands, you need to decide what design you will implement. There are at least three designs of wood splitters, fundamentally different from each other:

- wood splitter with hydraulic mechanism;

- wood splitter with rack and pinion mechanism;

- step-screw wood splitter.

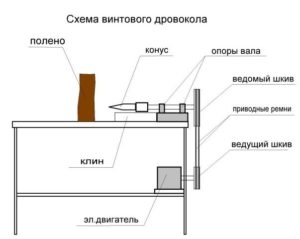

Having considered all the options, our experts came to the conclusion that it is better to start making a drawing of a screw wood splitter. Its design is simpler, more compact, has fewer elements, and therefore is cheaper. Thanks to the screw wood splitter, the process of splitting firewood is significantly accelerated. What is a screw log splitter?

This unit consists of several main elements:

This unit consists of several main elements:

- frames;

- washing machine motor;

- drive mechanism;

- special cone.

The essence of his work boils down to the following. The washing machine motor rotates a small pulley. By means of a belt drive, the work is transferred to a large pulley, which is mounted on a shaft. At the other end of the shaft there is a special sharp cone with thread. The shaft together with the cone are parallel to the ground and rotate. The chock is pushed onto the rotating cone strictly sideways, the cone is screwed into the chock from the side, quickly splitting it in half. This is the design we have to implement with our own hands, but first let’s select the necessary tools and materials.

Important! If you feed the wood end-on to the cone, the wood will get between the frame and the cone, jam and break it, rendering the wood splitter unusable.

We select everything you need

To assemble a homemade screw wood splitter you will need a relatively small set of tools, minimal skills in working with electric welding and a multimeter, as well as materials. What tools do you need?

- Electric welding with a set of 3 mm electrodes.

- Drill.

- Bulgarian.

- Pliers.

- Grinding wheel.

- Vise, anvil.

- Various screwdrivers, files.

- Ruler, pencil.

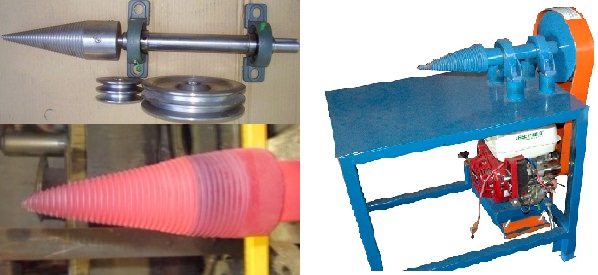

With materials everything is more complicated. Currently, there are quite a lot of videos on the Internet that demonstrate the operation of a screw wood splitter. These videos demonstrate at least several options for assembling the unit, but the essence of all options is the same. First you need to find the main part - the cone. You can’t buy such a thing in a store, and it’s very difficult to make it yourself, because the cone is first turned out, and a thread is cut on it with a short pitch.Next, the cone is heated red-hot and maintained in this state in the oven for half an hour, then sharply cooled in warm salted water.

There may be problems with making a cone, but do not despair, there are online stores where you can relatively inexpensively purchase ready-made hardened cones, specially designed for homemade wood splitters. There you can also buy all the necessary parts for the gearbox, such as a shaft, a small and large pulley, a belt and bearings. If you yourself have experience in manufacturing gearboxes and you have spare parts for them, then you can limit yourself to buying a cone; in all other cases, our experts recommend buying a “kit for a homemade screw wood splitter.”

In addition to the gearbox and cone, we will need a strong and reliable frame; we will weld it from steel corners, sheets, and also some parts of an old Soviet washing machine. Prepare in advance approximately 4.5 m of steel angle 40 mm, a rectangular sheet of metal 900x450 mm and a VAZ 2101,02,03,04,05,06 or 07 cardan suspension. If you don’t have parts from such washing machines in the garage, then everything you need can be pick it up for a pittance. Also, for the convenience of moving the wood splitter, you can weld two wheels from a medical gurney, a children’s bicycle, etc. to the frame; they also need to be prepared.

For your information! For our purposes, you can take a part of the cardan from any rear-wheel drive Soviet or Russian washing machine.

There remains one more part, without which our screw wood splitter will not work - the engine. We are making a wood splitter with a washing machine motor, so we need to disassemble any old washing machine with a brushed motor, remove the last one, use a multimeter to make sure it works and cook it.Well, that's all in general terms. In addition to all of the above, we will need various fasteners, but we don’t need to talk about them separately, and so it’s clear, let’s move on to the most interesting thing - making a cone log splitter.

Assembling the product

Let's assemble a cone log splitter with our own hands, which will turn the preparation of firewood from torture into pleasure. We'll start by making the frame. We cut a corner with a grinder, 2 pieces of 1400 mm each, 4 pieces of 200 mm each and one piece of 450 mm. We lay two 1400 mm corners in parallel at a distance of 450 mm each, connect the ends of the long corners with the letter “P” with a short 450 mm corner and weld the joint. Next, we retreat 900 mm from the welded joint and weld the cardan suspension element between the corners. Between the hanger and the first welded joint we place our rectangular steel sheet (it will fit exactly in size) and weld it.

Now all we have to do is weld 4 legs (4 pieces of 200 mm each) along the edges of the structure, attach wheels to two legs and the frame is ready. Next, let's take a look at the gearbox. We insert a shaft into the suspension element and put a large pulley on it on one side.

Important! In order to press the cone and pulley onto the shaft, the latter will have to be heated strongly using a blowtorch.

The next stage is very important. You need to put a small pulley on the motor shaft, and secure the engine under a welded suspension so that the small pulley is exactly under the large one. Mount the engine as securely as possible, since the structure will vibrate strongly during operation. We connect the pulleys with a belt. The free end of the shaft (intended for the cone) is equipped with “eared” bearings, the latter must be securely bolted to a metal sheet.

Next, we connect the two motor wires to the machine with our own hands, and then we connect the power cable to it and check how the motor will work in tandem with the gearbox, whether there will be any slippage or jamming. If everything is in order, we install the cone and check how our new wood splitter will work. The work is finished. If the engine does not work for some reason or there are problems connecting it, read the article How to connect the motor from a washing machine. Everything is explained there, and if it’s still not clear, watch the explanatory video.

Note! Before you start using a new screw wood splitter, watch the video on how to do it correctly; I wouldn’t want you to ruin something you’ve laboriously made with your own hands.

In conclusion, we note that we have just given you another option for an excellent economic use of a washing machine motor. We hope you will be able to bring this idea to life and assemble a wonderful screw wood splitter. After reading the text of this publication, be sure to watch the video below. Good luck!

Interesting:

2 reader comments

In the video, the motor is 4 KVA, but will it handle 180 W with a washing machine?

A washing machine with a commutator motor has a shaft speed of 15,000. Here the gear ratio is incorrect, just to write an article. I'm tired of illiterate schoolchildren who don't understand what they're writing about.