What does direct drive mean in a washing machine?

The direct drive inverter motor is a technology actively promoted by advertisers. The first sample was released by LG. It is believed that such a system eliminates wear and tear on moving elements, and the product receives improved performance characteristics and allows owners to save money. Manufacturers emphasize such models of household appliances over their belt-driven counterparts. But even the highest quality and most technologically advanced samples have drawbacks. Let's try to figure out what direct drive is in a washing machine, and what its real pros and cons are.

The direct drive inverter motor is a technology actively promoted by advertisers. The first sample was released by LG. It is believed that such a system eliminates wear and tear on moving elements, and the product receives improved performance characteristics and allows owners to save money. Manufacturers emphasize such models of household appliances over their belt-driven counterparts. But even the highest quality and most technologically advanced samples have drawbacks. Let's try to figure out what direct drive is in a washing machine, and what its real pros and cons are.

What kind of innovation is this?

The operation of this type of drive is based on the rotary or linear movement of electromagnetic energy. The load on the rotor in such structures occurs using an air gap. It is assumed that this fact eliminates wear of moving elements.

The drive itself serves as a design element for each model. Direct drive machines are actively produced by Whirlpool, Sears and other well-known brands that produce washing equipment.

Standard type models use a belt method to rotate the drum. It is attached to a belt, which, in turn, ensures the transmission of torque from the shaft. Main disadvantages:

- a belt that must be systematically replaced due to wear;

- high level of noise and vibration during operation.

When samples with a new type of motor were introduced into production, there was no longer a need to equip the engine with contacting elements. It has no brushes or belts.This is how manufacturers explain the high level of reliability of their models.

Main advantages of direct drive

The technology causes conflicting reviews from consumers and specialists who service equipment. For some buyers, the presence of an inverter electric motor is a serious argument, while others prefer already trusted models. Opinions are divided, but there are common positive points that relate to the advantages of the model:

- High performance characteristics. The long service life is due to the absence of contacting parts – brushes. Inverter-type motors, unlike asynchronous and commutator motors, do not have them.

The manufacturer claims a 10-year warranty on the operation of the motor.

- Low noise level. When operating such models, noise is of course present, but it is much less, especially if the equipment is installed according to all the rules.

- Washing quality. The brushless motor is characterized by fully electronic control. Its capabilities and additional functions allow you to take the process to a higher level.

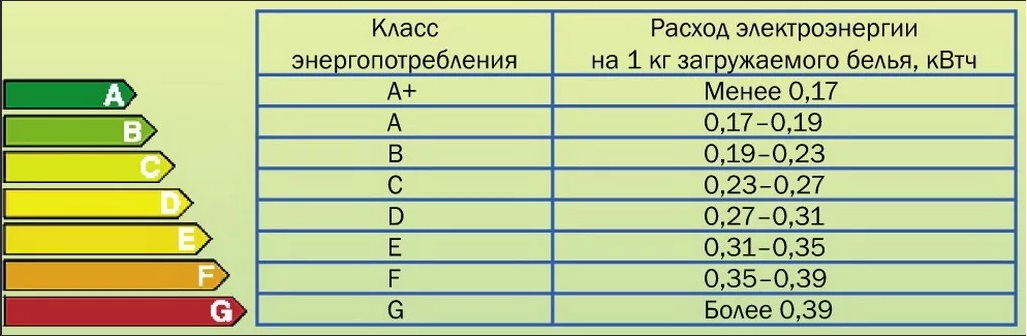

- Energy saving. The successful design of the drive allows you to spend less energy on accelerating the drum. The result is energy savings.

- Warning about errors in operation and stopping the program until the problems are resolved.

- Compact dimensions. The absence of a pulley and belt allowed manufacturers to significantly reduce the size of machine bodies, which affected the appearance and ease of use.

Disadvantages of technology

Along with obvious advantages, direct drive models have a number of disadvantages. Knowledge about the disadvantages encourages manufacturers to improve equipment, and consumers to thoughtfully approach the choice of machines.

- The absence of a belt entails additional load on bearings and seals. The failure of these elements cannot be called budget savings.

- Potential vulnerability of the motor. Its location under the drum when the bearing is destroyed creates the possibility of failure because water gets on the engine. The terms of the long-term warranty do not apply to this type of breakdown; repairs are expensive.

- Electronics. The entire system is controlled by a complex module, which, in general, is not known for its reliability. Problems with firmware and failure of triacs are a common occurrence, especially if there is a problem with the electrical network in the house. To ensure uninterrupted operation of the machine, it is better to buy a stabilizer and connect the equipment through it.

- Price. A determining criterion when choosing for a larger number of consumers. The cost of direct drive models is an order of magnitude higher than their belt-driven predecessors.

The list is not so long; in general, machines with this technology performed well due to significant advantages in the form of quietness, aesthetic design and ease of operation. Manufacturers are directly interested in improvement, which will lead in the near future to eliminating these shortcomings.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment